#1: JUICE comes in from extreme temperature test

7 June 2018

This is the first entry in the JUICE Test Campaign Journal, a series of articles covering the main events during testing of the Thermal Development Model (TDM), the Engineering Model (EM) and the Proto-Flight Model (PFM) of the spacecraft. The mission is scheduled to launch in 2022 to investigate the Jupiter system. |

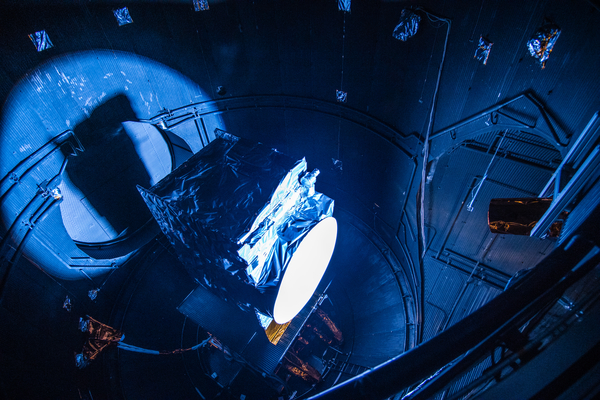

| The JUICE Thermal Development Model and the Sun Simulator. Credit: ESA–M.Cowan |

One of the major challenges facing ESA's JUICE (JUpiter Icy Moon Explorer) will be the extreme temperatures that the spacecraft and its suite of instruments will have to endure.

In order to ensure that the orbiter survives the voyage to Jupiter and the cold, hostile environment of the Solar System's largest planet, the spacecraft will have to pass a series of challenging tests during its lengthy development process. The first of these – known as a Thermal Development Model (TDM) test – was recently completed.

The objective of the test, which took place between 5 and 10 May at ESA's technical centre in The Netherlands, was to verify that the spacecraft's thermal control system could protect the spacecraft from extreme temperatures during its complex mission.

| JUICE's journey to Jupiter. Credit: ESA |

After launch, JUICE will embark on an 88-month cruise that will make use of several flybys – of Earth, Venus, Earth, Mars, and again Earth – before leaving the inner Solar System on its way to Jupiter.

En route, the spacecraft will have to endure the effects of solar heating, particularly during the flyby of Venus. Eventually, it will have to operate in an extremely cold environment where some of its external surfaces will experience temperatures below -200 degrees Celsius after arrival at Jupiter, with even colder conditions during solar eclipses, when the spacecraft will be in the planet's shadow.

The JUICE thermal control system is designed to minimise the impact of the external environment on the spacecraft through the use of high efficiency Multi-Layer Insulation (MLI). The material that is used to blanket the spacecraft's exterior is known as StaMet coated black kapton 160XC.

The MLI will moderate the external temperature during the spacecraft's closest approach to the Sun. It must also limit heat leakage in the cold Jupiter environment in order to minimise demand for power from the spacecraft's heaters, especially when its instruments are operating during the science and communication phases.

The power demand will be a crucial factor during operations given the limited power generated by the spacecraft's solar panels at Jupiter's distance from the Sun, where the amount of incoming solar energy is 25 times lower than on Earth.

Efficient passive thermal insulation also minimises hardware mass – always a major concern for spacecraft designers – by reducing the need for radiators and heaters.

Thermal verification test

The thermal verification test was required to check the passive heat loss properties of the spacecraft in both cold and hot environments. It used a full scale model, the TDM, which comprised a simplified version of the JUICE flight model structure.

|

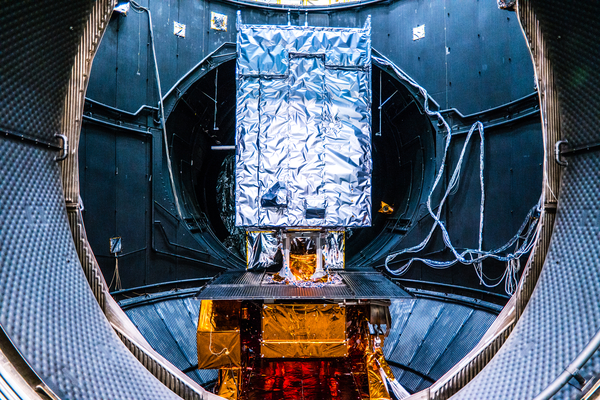

| The JUICE TDM inside the Large Space Simulator. Credit: ESA–M.Cowan |

The spacecraft's central cylinder was replaced by a basic hexagonal structure and the High Gain Antenna (HGA) was simulated by a simple, white-painted aluminium disc with the same diameter as the HGA flight model. This was relevant for the test, because the HGA will be used as an umbrella shielding the structure when the spacecraft will be at its closest to the Sun.

There were no other protruding instruments or appendages on the TDM, but heat dissipation from the platform and internal instruments was simulated by adding test heaters.

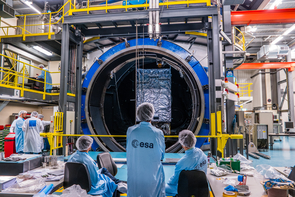

The TDM itself, wrapped in MLI, was placed in the Large Space Simulator (LSS) at ESA's European Space Research & Technology Centre (ESTEC) in Noordwijk, the Netherlands. Operated by European Test Services, the LSS is the largest space simulation facility in Europe, enabling a wide variety of tests to be performed on spacecraft.

|

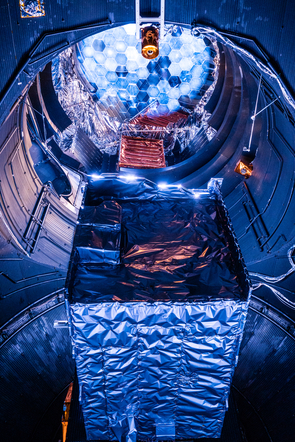

|

| The JUICE TDM inside the Large Space Simulator, before (left) and after (right) closing the 5-m diameter side door. Credit: ESA–M.Cowan | |

Engineers began pumping the air out of the 9.4-m diameter chamber on 5 May, in order to create a vacuum comparable to the airless environment of deep space. This vacuum was maintained throughout the test.

|

| The JUICE TDM and the Sun Simulator. Credit: ESA–M.Cowan |

The first phase of the thermal verification test involved the use of the Sun Simulator – a system of high-energy lamps and mirrors – to raise the 'external temperature of the TDM to around 200 degrees Celsius on the side that will face the Sun.

At the same time, thermal shrouds cooled by liquid nitrogen were used to lower the temperature inside the chamber to -180 degrees Celsius, in order to simulate the cold conditions of the sides that will face away from the Sun. During this hot phase, the MLI was expected to maintain the structure's temperature at a modest 35 degrees Celsius.

This was followed by the cold phase, which simulated the low-temperature environment at Jupiter by maintaining the frigid conditions inside the chamber and switching off the Sun simulation lamps. Meanwhile, the heat output from the test heaters was increased to simulate the output from the spacecraft's onboard instruments.

Once the testing was completed, air was pumped back into the chamber until it reached normal pressure and temperature. The thermal verification test ended on 12 May, when the chamber door was opened.

"The test was very successful and proceeded very smoothly," said Ared Schnorhk, Assembly, Integration, and Testing (AIT) manager at ESA. "This allowed us to perform an additional phase with the Sun Simulator operating at an intermediate intensity.

"The measurements recorded from more than 380 thermocouples will be analysed in the coming weeks. The results will provide a solid basis for the JUICE Critical Design Review, which will start in mid-December 2018."

Further tests of other JUICE components are planned for later in the year. These will include:

- a pattern test of the RIME antenna (an instrument that will study the liquid water oceans beneath the icy moons);

- qualification of the GALA diode (the laser altimeter that will map the profiles of the moons);

- delivery of the spacecraft Engineering Model, using a representative full scale model of the spacecraft structure;

- the beginning of the functional validation campaign.

After completion of the Critical Design Review, the integration of the JUICE flight model will begin.

About JUICE

JUICE – JUpiter ICy moons Explorer – is the first large-class mission in ESA's Cosmic Vision 2015-2025 programme. It will complete a unique tour of the Jupiter system that will include in-depth studies of three potentially ocean-bearing satellites, Ganymede, Europa and Callisto.

The Jupiter tour includes several flybys of each planet-sized world, and it ends with orbit insertion around Ganymede, the largest moon in the Solar System.

JUICE will carry the most powerful scientific payload ever flown to the outer Solar System. It consists of 10 state-of-the-art instruments plus one experiment that uses the spacecraft telecommunication system with ground-based instruments.

JUICE's instruments will enable scientists to compare each of these icy satellites and to investigate the potential for such bodies to harbour habitable environments such as subsurface oceans. They will also carry out observations of Jupiter, its atmosphere, magnetosphere, satellites and rings.

About the Thermal Development Model

The JUICE Thermal Development Model was built by Airbus Defence and Space S.A.U. (Spain) under contract with Airbus Defence and Space SAS (France). Part of the structure and the thermal control system were manufactured by HPS (Portugal) and RUAG (Austria), respectively.