Latest LISA Pathfinder hardware delivery is 'Jewel in the Crown'

24 June 2013

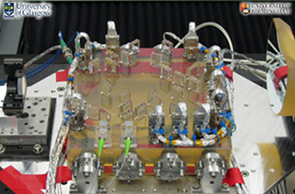

A team of scientists from the University of Glasgow has successfully delivered a significant milestone for LISA Pathfinder - the flight optical bench. This glittering piece of hardware has very demanding requirements; tests have shown that these have been exceeded. Following formal delivery to Astrium GmbH, on 21 June, the optical bench is ready for integration onto the LISA Technology Package (LTP).LISA Pathfinder is a mission to test the technology required to detect gravitational waves in the range of 0.1 to 100mHz. Due to noise caused by vibrations on the Earth, these gravitational waves can only be detected from space. The effect of the passage of the gravitational waves through the detector is so miniscule, that ultra-sensitive instruments are required to record the signal – requiring that each subsystem of the instrument is also ultra-sensitive.

|

|

LISA Pathfinder flight optical bench. |

The optical bench allows laser interferometry to be used to accurately monitor two free-falling test masses for changes in attitude and the distance between them.

The masses are cubes of highly polished gold-platinum alloy situated 38 cm apart in dedicated vacuum enclosures inside the satellite, and act as mirrors to reflect the laser beams.

To protect the test masses from external forces, the LISA Pathfinder mission will fly the spacecraft so that the masses stay in the middle of their enclosure and do not touch the sides.

In optical systems, the accurate alignment of components is extremely important – the goal of the interferometric measurement system of LISA Pathfinder is to monitor the separation of the test masses to a small fraction (~100,000th) of the wavelength of the light being used to make the measurement. (The light used for the measurement has a wavelength of 1064 nm, and is produced by an Nd:YAG non-planar ring oscillator laser.)

The optical bench holds all of the components. Standard optical benches usually consist of an extremely rigid table with a flat top surface, such that the components can make good contact with the table. However, for LISA Pathfinder, the bench and components attached to it had to meet many stringent requirements – for example, the optical path must be extremely stable, it must be able to withstand changes in temperature between about 10 °C and 40 °C and it must be robust enough to survive launch vibration - and still be accurately aligned after launch.

“The optical bench is made from a 20cm by 20cm block of Zerodur ceramic glass, and is the centre piece around which the rest of the payload can be built,” says Paul McNamara, LISA Pathfinder Project Scientist at ESA.

“The lasers must be directed onto the test masses with an accuracy of microns. The laser beam is about 1.2mm in diameter, and we have to position it to about 10 microns (about 100th of the beam diameter). Because of the shape of the beam we end up having to position the centre of a flattish surface - the beam - to a given position in 3D space so that it hits the test masses at the right place,” he explains. “The bench is built WITHOUT the test masses being in place - the only information the team have when building it are the nominal coordinates of the test mass position. This is where the expertise comes into the integration,” he adds.

As LISA Pathfinder is testing the technology for detecting low-frequency gravitational waves, it is important to know the amount of noise in the instrumentation. The most interesting frequencies – corresponding to the acceleration of massive objects (such as black hole mergers) - have been calculated to have a period of hundreds of seconds or more. In order to detect such signals, other noises must be carefully filtered out. The detection sensitivity is limited by the intrinsic noise of the measurement system in a specific frequency band. For this reason, the instrument noise is normally referred to as an "amplitude spectral density" and all measurement units are specified in "per square root Hertz" (/√Hz) at a particular frequency. For LISA Pathfinder, the noise must be measured to a sensitivity of the order of a few picometres per square root Hz at 3 mHz (a picometer (pm; 10-12 m) is smaller than the radius of an atom of Hydrogen).

To gain this type of accuracy, the bench is made of Zerodur ceramic glass. It can be polished to a very flat surface, and it barely contracts or expands when subjected to changes in temperature. The thermal coefficient of expansion (CTE) of Zerodur is almost zero (CTE = 0.02×10-6/K). For comparison, Pyrex, a heat resistant material often used for household glassware, has a CTE about 150 times larger than this, CTE = 3.2×10-6/K . For use in space, optical benches are often made from Silicon Carbide, which has a CTE ~4-5×10-6/K.

|

|

|

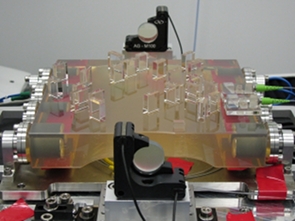

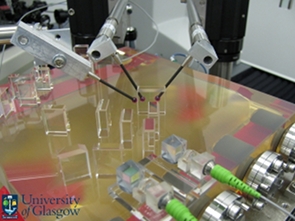

Left: LISA Pathfinder flight optical bench during construction; Right: Constructing the LISA Pathfinder flight optical bench. Credit: University of Glasgow |

|

“The optical bench is the jewel in the crown of LISA Pathfinder, quite literally, as it looks like it is full of shiny tombstones - the mirrors and beam splitters,” notes McNamara.

Conventional glues expand and contract at different rates, and so are unsuitable for such precision work in the temperature ranges found getting to and operating in space. The bonding of the components onto the optical bench therefore had to be re-examined.

“As we are trying to measure such small displacements, we cannot afford to have the components move about – and joints glued together tend to move. The technique we chose to use is hydroxide catalysis bonding, which fuses the two surfaces together, forming a molecular bond, with no resulting losses. The result is not just strong – it is ultra strong. If the two items are then able to be pulled apart, the failure will not occur at the joint, but at a flaw elsewhere in the material,” explains McNamara.

Hydroxide catalysis bonding was first developed at Stanford University for use on NASA’s Gravity Probe B (GPB) mission. The technique has since been used on ground-based interferometer detectors, such as the GEO600, and scientists at the University of Glasgow have developed it further for use on LISA Pathfinder.

The bonding process is extremely quick – there is no waiting for the glue to cure, during which time the component may shift. “If you try to move the components after more than a few tens of seconds, you will have to re-polish both surfaces. After a minute or so it cannot be taken apart without destroying both sides. This does make the process a little stressful for the scientists building the optical bench,” says McNamara.

After bonding the components onto the optical bench, the subsystem was extensively tested at the Institute for Gravitational Research (IGR) at the University of Glasgow. It exceeded the requirements set for it.

The optical bench has been delivered to Astrium in Germany, where it has been tested and is still aligned and working perfectly. As the optical bench sits in the centre of the payload, it will be one of the first subsystems to be integrated into the LTP. The integration should start in the next few weeks.

About LISA Pathfinder

LISA Pathfinder is a European Space Agency mission to test the technology required to detect gravitational waves in the range of 0.1 to 100mHz. The mission will demonstrate critical technologies for future gravitational wave observatories, in a space environment. These technologies include: gravitational reference sensing, drag-free attitude control, and interferometry with free-falling mirrors.

An industrial team led by the prime contractor, Astrium Ltd, is building LISA Pathfinder. Astrium GmbH is responsible for providing the integrated LISA Technology Package (LTP) payload from the subsystems delivered by several European Member states and ESA. The optical bench, a part of the LTP, is provided by the University of Glasgow, United Kingdom. Key components of the bench are provided by the University of Birmingham. Mullard Space Science Laboratory is the UK national project manager of the optical bench. The Nd:YAG laser is provided by Tesat. For a more complete list of contributions to the LISA Pathfinder mission, please visit this page.

Contacts

Paul McNamara

LISA Pathfinder Project Scientist

Directorate of Science and Robotic Exploration, ESA, The Netherlands

Email: Paul.McNamara@esa.int

Phone: +31-71-5658239

César García Marirrodriga

LISA Pathfinder Project Manager

Directorate of Science and Robotic Exploration, ESA, The Netherlands

Email: Cesar.Garcia@esa.int

Phone: +31-71-5655172