ExoMars 2018 Test Campaign Journal: #01 - ExoMars Rover Sample Preparation and Distribution System Tested Under Martian Conditions

4 July 2013

This is the first entry in the ExoMars 2018 Test Campaign Journal, a series of articles covering the main events during the development, integration and testing of the ExoMars rover. The engineering prototype of the Sample Preparation and Distribution System has recently completed testing under simulated Martian conditions.The engineering prototype, or 'breadboard', of the Sample Preparation and Distribution System (SPDS), which will form part of the Analytical Laboratory Drawer (ALD), has already undergone extensive testing under ambient Earth conditions at the facilities of the development contractor, Kayser-Threde GmbH, in Munich, Germany. In mid-March, the prototype was transported to Aarhus University in Denmark for testing in a Mars simulation chamber.

| Testing the ExoMars Sample Preparation and Distribution System 'breadboard' in a simulated Martian environment. Credit: Kayser-Threde GmbH Click here for more information about this video |

Testing in a simulated Martian environment was designed to investigate the performance of the various SPDS mechanisms that will collect, pulverise and deliver the samples for analysis in the extreme cold they will encounter on the planet's surface (average ~ -60°C) and in a rarefied (~ 0.5 kPa - 0.6% of Earth value), mainly CO2 atmosphere.

The ALD/SPDS will be inside the warm body of the rover and will be temperature controlled. The non-operating temperature will range from -50°C to +60°C; the operating temperature will range from -40°C to +40°C. Sample processing will only be done in a cold case, since the sample must remain below -5°C during processing.

During these tests, the mechanisms were tested at the worst case of -50°C to -55°C. Operating in extreme cold influences the selection of materials, particularly with regard to differential expansion. The requirement for the SPDS to operate in near vacuum affects the choice of lubricants and the design of bearings. The mechanisms also need to survive the Dry Heat Microbial Reduction process, which will be used to 'sterilise' parts of the spacecraft prior to launch, at +125°C.

About the SPDS

|

|

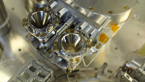

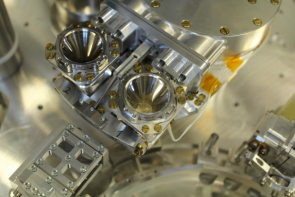

| Core Sample Transportation Mechanism. Credit: Kayser-Threde GmbH |

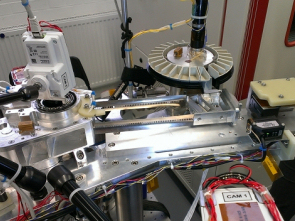

Crushing Station. Credit: Kayser-Threde GmbH |

One of the rover's main objectives will be to analyse rock and soil samples collected from various subsurface depths using a suite of next-generation instruments. The samples will be collected by a drill and delivered to the Core Sample Handling System (CSHS) component of the SPDS, which is made up of the Core Sample Transportation Mechanism (CSTM) and the Blank Sample Dispenser (BSD). The CSTM will carry the samples into the ALD, where they will be released through a trapdoor into the Crushing Station (CS) and be reduced to powder. The BSD will deliver 'blank' samples brought from Earth for verification purposes. The powdered samples then pass from the CS to the Powder Sample Dosing and Distribution System (PSDDS).

|

|

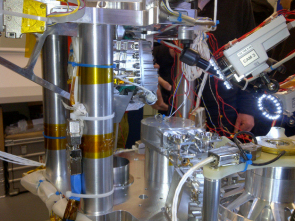

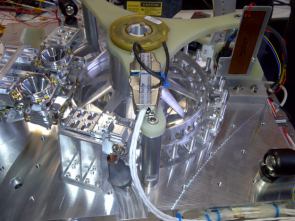

| Powder Sample Dosing and Distribution System. Credit: Kayser-Threde GmbH |

Powder Sample Dosing and Distribution System with sample. Credit: Kayser-Threde GmbH |

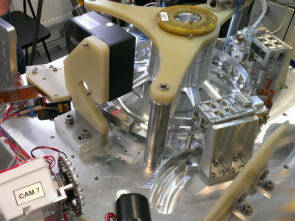

The PSDDS delivers a measured quantity of powder into the Refillable Container (RC) that is mounted on the Powdered Sample Handling System (PSHS). The PSHS is a carousel that moves the samples to various stations for processing and analysis. One station is equipped with a fixed 'scraper', the Powder Sample Flattening Mechanism (PSFM), which levels the surface of the powdered sample in the RC. Another station houses the Refillable Container Cleaning Mechanism (RCCM), while further stations will have instruments to examine the surface of the samples and pyrolysis ovens to feed the MOMA GC-MS.

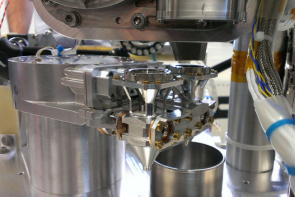

|

|

| Powdered Sample Handling System. Credit: Kayser-Threde GmbH | |

About the ExoMars 2018 Mission

The second mission of the ExoMars programme, which is scheduled to be launched in 2018 and to arrive at Mars nine months later, consists of a European rover and a Russian surface platform.

The ExoMars 2018 mission will be carried out by ESA in partnership with Roscosmos. ESA will provide the carrier module and the rover, while Roscosmos will supply the descent module, surface platform and launcher. Instruments for the rover science payload are provided by European and Russian institutes. The Prime Contractor for the rover is Thales-Alenia Space Italy.