NIRSpec Reaches Milestone

2 November 2007

The NIRSpec instrument recently successfully passed the Mandatory Inspection Point (MIP) of its FORE optical system. The FORE optical system re-images a fraction of the focal plane of the 6.6 metre diameter JWST optical telescope onto the NIRSpec Micro-Shutter Array (MSA), which is a transmissive MEMS system used to select the scientific targets that are to be observed by NIRSpec.Like most of NIRSpec, the FORE optical system is made out of silicon carbide (SiC). This ceramic material is ultra-stable and ultra-stiff. The very high stiffness to weight ratio and the good ability to polish allow manufacturing of highly light weighted mirrors with extreme good optical and straylight characteristics, perfectly suitable for cryogenic applications.

|

|

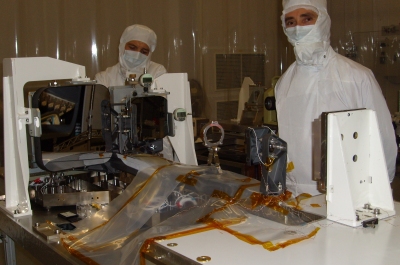

The NIRSpec FORE optical system during alignment. Credit: Sagem |

The FORE is one of the three core optical modules of the NIRSpec instrument, each of which is a three mirror anastigmat (TMA) optical system. Verification of the FORE optical system was performed by Sagem, the company responsible for polishing, alignment and cryogenic optical verification of the three core NIRSpec optical modules.

Sagem succeeded polishing and aligning FORE's complicated TMA optical system and only two iterations were needed to reach the required optical performance at ambient. All main ambient optical performances were verified and fulfilled, and sometimes even exceeded, the requirements. Typical end-to-end wave front errors were recorded to be of the order of 35-45 nm RMS. The optical system also appeared to be totally free of any so-called vignetting. Presence of vignetting would mean that somewhere in the opto-mechanical system parts of the beams are being blocked by limited optical apertures or surrounding mechanical structure.

The next step in the FORE verification process is the cryogenic optical performance verification, performed at 35 K. Previous cryogenic optical testing on SiC test mirrors during an ESA funded technology study has already demonstrated extreme low surface deformations as a result of cryogenic cool down.