Latest LISA Pathfinder hardware is a little gem

18 November 2008

A stunning sapphire and gold casket is the latest addition to the LISA Pathfinder flight hardware collection. Designed to house the LISA Technology Package proof masses the casket is now undergoing experiment characterisation tests in Italy.The 'precious' core of the LTP

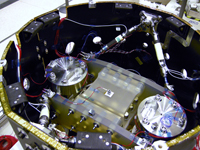

At the core of the LISA Pathfinder spacecraft resides the LISA Technology Package (LTP) which is designed to demonstrate the technology needed for the LISA mission. The LTP is composed of two vacuum containers connected by an optical bench (see Figure 1), each containing a proof mass enclosed in an electrodes housing box.

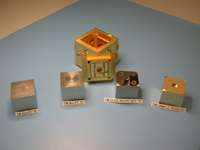

The proof mass is a cube of 46 mm on a side, weighing about 1.96 kg, and made from a special alloy of approximately 73% gold and 27% platinum (see Figure 2). This alloy has been specifically chosen in order to minimise the susceptibility of the material to external magnetic fields. In order to fulfil its experimental role the proof mass must not be perturbed by magnetic fields generated by the spacecraft electrical units or those intrinsic to interplanetary space.

The proof masses are in many senses the 'precious' core of LISA Pathfinder, as they are the material bodies that will follow a pure free-fall trajectory during the mission. They will also be the gravitational wave sensors in the LISA spacecraft.

Sapphire and gold caskets for the precious proof masses

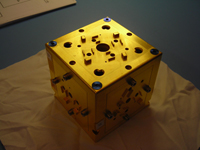

As would be the case for any precious object each LISA Pathfinder proof mass is contained in a beautiful casket (the electrodes housing box, or EH), in this case constructed from sapphire and gold (see Figure 3).

On 4 November the first flight-like EH was delivered by its manufacturer, Thales Alenia Space Italy of Milan (formerly Laben), to the University of Trento, Italy, for experiment characterisation tests. During these tests, a "torsional pendulum" is used to reproduce, in two degrees of freedom, nearly the same conditions of free-fall that will be experienced by LISA Pathfinder. Measurements will be made using the pendulum, to check that when the proof mass is inside the electrodes housing it behaves as expected in terms of coupling with the EH, and also to check that the EH is without defects.

|

|

|

Figure 3. The electrodes housing box. One of the sides is left unmounted (left) until the proof mass has been inserted at which stage the final side is attached (right). Credit: ESA | |

The EH, a cube measuring about 70 mm on a side, contains the proof mass with a gap of only 4 mm. This gap allows the proof mass to float inside the EH once LISA Pathfinder is in space. On each of the six sides of the box, sapphire electrodes, especially manufactured by Kyburz-Sapphire in Switzerland, will be used to create an electrostatic field across the proof mass in order to sense its position with high accuracy in all directions (2 nm/sqrt Hz). The electrodes also provide electrostatic forces which will gently maintain the cube in the centre of the EH during the experiment.

A challenging manufacturing process

The manufacturing of this extremely sophisticated box has proved to be a real challenge for the industrial team. The individual sapphire electrodes must be:

- accurately polished to a roughness not exceeding 2 microns,

- coated with a layer of Manganese,

- their edges accurately chamfered,

- the faces marked with a small Laser cross for alignment,

- 3D precision measured,

- coated with a layer of Rhodium and Titanium,

- brazed on Molybdenum frames,

- and finally, assembled with a special quartz mandrel and adjusting pins.

|

|

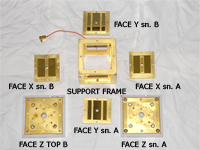

Figure 4. Individual elements of the electrodes housing (EH) box. When assembled the EH will house one proof mass within the LISA Technology Package on LISA Pathfinder. Credit: ESA |

All of the parts are first assembled to check that everything fits correctly; they are then disassembled (see Figure 4), the electrodes finally coated with gold, the special connector pins inserted and the EH is then reassembled again. One of the sides is left unmounted to allow for the insertion of the proof mass at a later date.

The manufacturing process has required the box parts to travel across Europe to specialised laboratories and workshops in Switzerland, Germany and Italy.

Not only does the final product comply to specifications, it is also beautiful - a stunning addition to the LISA Pathfinder hardware collection.