Payload

|

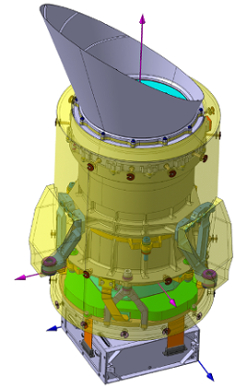

| Schematic figure of one of the cameras of the PLATO spacecraft. Credit: PLATO Mission Consortium |

The key scientific requirement to detect and characterise a large number of terrestrial planets and their host bright stars determined the design of PLATO's payload module. The module provides a wide field-of-view (FoV) to maximise the number of the sparsely distributed bright stars in the sky with one pointing, and allows the satellite to cover a large part of the sky. In addition, it provides the required photometric accuracy to detect Earth-sized planets and a high photometric dynamic range, allowing astronomers to observe bright stars (mV < 11) as well as fainter stars down to V-magnitude of 16. This performance is achieved by a multi-telescope instrument concept, which is novel for a space telescope.

The payload consists of 24 'normal' cameras operating in the visible wavelength range. They will be read out with a cadence of 25 s and will monitor stars with mV > 8. Two additional 'fast' cameras with high read-out cadence (2.5 s) will be used for stars with mV ~4-8. The 'normal' cameras are arranged in four groups of six. Each group has the same field-of-view but is offset by a 9.2° angle from the payload module +Z axis, allowing astronomers to survey a total field of about 2250 deg² per pointing, but with different sensitivities over the field.

The ensemble of instruments is mounted on an optical bench. The cameras are based on a fully dioptric design with 6 lenses. Each camera has an 1100 deg² field-of-view and a pupil diameter of 120 mm and is equipped with a focal plane array of 4 CCDs each with 4510×4510 pixels of 18 μm size, working in full frame mode for the 'normal' camera and in frame transfer mode for the 'fast' cameras.

Contributions to the Payload

| Management of the PLATO payload hardware and on-board software elements developed by ESA and the PLATO Mission Consortium (PMC), including system engineering, assembly integration and verification (AIV), product assurance and project management.

Lead the assembly, integration and functional testing of the PLATO payload. Engineering support for the development of the camera systems. CCDs |

ESA |

| Co-Principal Investigator Telescope Optical Units Instrument Control Unit and relevant onboard software Manage the camera system, including system engineering, assembly integration and verification (AIV), product assurance and project management. Lead the assembly, integration, and functional testing of the normal and fast camera units. Support ESA in the integration and verification of the instrument, in-orbit commissioning, and instrument operation. |

ASI, Italy |

| Principal Investigator Support for systems engineering Fast Front-End Electronics Data Processing System Fast Electronics Unit including the Fine Guidance System and onboard software Performance monitoring & assessment Support ESA in the integration and verification of the instrument, in-orbit commissioning, in flight calibration and instrument operation. |

DLR, Germany |

| Software for the data processing system of the normal telescopes Contribution to Fast Front-End Electronics Contribute to the camera assembly, integration and testing, and calibration activities. |

CNES, France |

| Co-Principal Investigator Focal Plane Assemblies mechanical and thermal architectures Main Electronic Unit, including the Data Processing Units for the normal cameras. Contribute to the assembly, integration and testing, and calibration of the Focal Plane Assembly at camera and system level and of the Main Electronic Unit at system level, including hardware, software and ground support equipment. Contribute to the camera assembly, integration and testing, and calibration. |

MICINN, Spain |

| Contribute to the camera assembly, integration and testing, and calibration activities. | SRON, The Netherlands |

| Design, analysis, and building of the Broadband Filter Coating part of the optical design of the fast telescopes | SNSA, Sweden |

| Co-Principal Investigator Normal Front-End Electronics Normal Analog chain calibration and characterization |

UK Space Agency |

| Router and Data Compression Unit in the Instrument Control Unit On-board data compression algorithms |

Austrian Aeronautics and Space Agency |

| Management of the assembly and integration, ambient alignment, and mechanical testing of the camera EM, QM, and FMs. Coordination of the overall assembly, integration and testing programme, and calibration at camera level as part of the camera team. Development of the common elements in the Electrical Ground Support Equipment (EGSE) for ambient and thermal-vacuum tests. |

Belgian Federal Science Policy Office |

| Development and production of the camera transport containers | Ministry of Transport and the Ministry of Education, Youth and Sports, Czech Republic |

| Front-end Support Structure for the normal and fast cameras | Norwegian Space Agency |

| Integration, verification, and delivery to ESA of the Optical Ground Support Equipment (OGSE) for camera testing Multilayer Insulation (MLI) |

Portugal Space Agency |

| Telescope Optical Units mechanical structure | Swiss Space Office |