#13: CHEOPS – chilled and checked, shaken and not stirred

31 August 2018

This summer, the CHEOPS satellite breezed through thermal tests in France and vibration tests in Switzerland, demonstrating that it is ready to operate in the extreme cold of space and also fit to withstand the mechanical stresses of launch. |

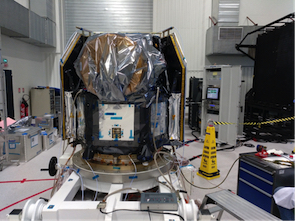

| Loading CHEOPS into the thermal-vacuum chamber at the Airbus Engineering Validation Test facility in Toulouse, France. Credit: ESA/Airbus |

Keeping the CHEOPS telescope and detector at a stable temperature will be vital for obtaining accurate measurements of the brightness of stars. Temperature variations of several degrees can cause small distortions in the telescope structure resulting in artificial changes in the measured star brightness.

Even more challenging requirements apply to the detector: CHEOPS will measure the minute changes in the apparent brightness of a star caused by the transit of an exoplanet across the stellar disc, and its detector must be stable to within a hundredth of a degree to ensure sensitivity to such small changes.

In orbit, the satellite will be warmed directly by the Sun, and it will also receive infrared light radiated by the Earth and sunlight reflected by the Earth's surface. In spite of these direct sources of heat, all the external surfaces on CHEOPS will be exposed to cold space and, if not heated, may easily reach temperatures as low as -200 degrees Celsius. As the satellite orbits the Earth and turns to observe different target stars, the illuminated areas will change all the time, causing temperature variations that, if not actively compensated, could degrade the accuracy of planetary transit measurements.

|

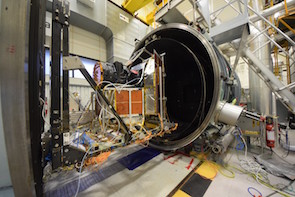

| The fully-integrated CHEOPS satellite before starting thermal testing. Credit: ESA/Airbus |

To counteract these variations, the satellite is equipped with a control system that uses onboard heaters to keep the telescope tube at a temperature of -10 degrees Celsius. The CCD detector, whose noise performance improves at low temperatures, will be cooled to an even lower -40 degrees Celsius.

The initial passive cooling of the detector is achieved by coupling it to dedicated radiators that are exposed to the cold of space; in addition, due to the extremes of heating and cooling experienced by the spacecraft, the detector assembly also makes use of high heat capacitance materials and is actively controlled by heater lines that limit temperature fluctuations to within 0.01 degrees Celsius.

Thermal vacuum tests that characterised the optical performance of the science instrument under the assumption of adequate onboard thermal control, were described in CHEOPS journal #9.

The latest thermal-vacuum tests, which took place between 20 July and 2 August at the Airbus Engineering Validation Test (EVT) facilities in Toulouse, France, aimed at ensuring that the onboard thermal control systems will do their job when subjected to realistic in-orbit conditions. These are the first thermal tests that have been performed on the integrated science instrument and spacecraft platform at realistic temperatures.

To this aim, the satellite was placed in a vacuum chamber and surrounded by shrouds cooled to -165 degrees Celsius using gaseous nitrogen. The black shrouds created a very cold, space-like environment that absorbed heat from the satellite. The warming effect of the Sun was simulated by mounting flat heater plates around CHEOPS and using them to cause rapid changes in heating that reproduced, or purposely exceeded, the range of conditions expected during operations. The temperature of the spacecraft was monitored at more than a hundred different places to observe its response to changes in external heating.

|

|

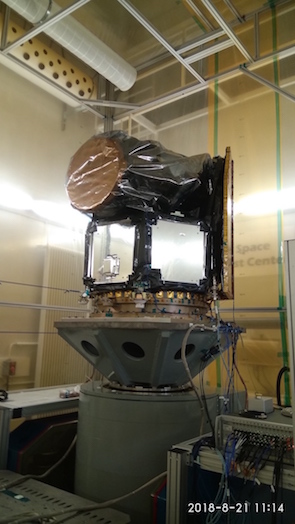

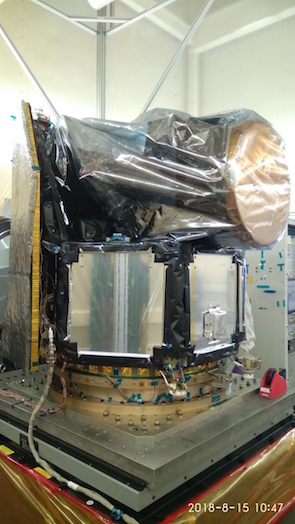

| Thermal-vacuum chamber tests for CHEOPS. Credit: ESA/Airbus | Inspecting the fully-integrated satellite. Credit: ESA/Airbus |

The test results have not only provided direct evidence that the thermal control systems perform correctly and that CHEOPS can operate in an extreme thermal environment, but have also returned a wealth of data that will be used to refine a 5000-node mathematical model of the spacecraft’s thermal behaviour. With this, it will be possible to accurately predict, by means of computer simulations, in-flight scenarios that are impractical to test directly.

Right after the thermal-vacuum tests were completed in France, the satellite was shipped to Zurich, Switzerland to perform mechanical vibration tests.

During launch on a three-stage Soyuz vehicle, CHEOPS will experience vigorous shaking: mechanical loads will be transmitted from the launch vehicle to the satellite at lift-off and during a series of subsequent thrust and separation events. Each of these events will cause vibrations at particular frequencies and the satellite must be able to withstand the entire spectrum of vibrations.

| CHEOPS vibration test: longitudinal shaking. Click here for details and large versions of the video. Credit: ESA/Airbus/RUAG |

On-ground vibration testing took place at RUAG Space, Zurich between 14 and 22 August using a high performance electromagnetic shaker to apply vertical and lateral sine-wave oscillations. The satellite has a one-off design and its construction has involved carefully considered choices about all details of manufacture, tolerances, accommodation of equipment, payloads, harnesses and other fittings. The purpose of this pre-flight vibration testing was to confirm that the satellite as built is robust to the rigours of launch.

There is a trade-off involved during vibration testing. If the loads applied are too weak, the satellite will be under-tested and unexpected failures could occur at launch, but if the loads are too strong, over-testing could lead to unnecessary failures during the test.

|

|

| CHEOPS vibration test: longitudinal shaking. Credit: ESA/Airbus/RUAG | CHEOPS vibration test: lateral shaking. Credit: ESA/Airbus/RUAG |

To find the optimum balance between under-testing and over-testing, the strength of vibration loads applied by the shaker at different frequencies has been fine tuned using mathematical simulations, to levels which meet the design specification and verification requirements of the Soyuz launcher in the particular case of CHEOPS. The fine-tuning was performed using so-called coupled loads analysis, taking into account the actual launch scenario, in which the satellite is secured to the launcher, and performing simulations based on the fully-assembled launcher.

These loads caused mechanical oscillations at different frequencies in the entire launch vehicle, and the corresponding dynamic responses of the CHEOPS satellite were predicted using a structural model of the satellite. In particular, the responses at the satellite-to-launch-vehicle interface of the coupled system served as reference during satellite vibration testing and a so-called notching procedure was implemented to reduce the vibration strength in particular frequency ranges and prevent over-testing.

The on-ground vibration testing has provided important confirmation that both the unique design and skilled workmanship of the CHEOPS satellite meet their mechanical requirements.

After the successful tests, the mission can now move to its next phase with confidence.

|

| CHEOPS arrival at ESA's technical centre in The Netherlands. Credit: ESA–G. Porter |

The satellite was shipped to ESA's technical centre in The Netherlands, where it arrived on 30 August, for acoustic noise and electromagnetic compatibility tests. Acoustic noise testing is complementary to the vibration tests performed in Zurich, exposing the satellite to vibrations up to and beyond 2000 Hz, whereas the mechanical vibration tests only reached frequencies as high as 100 Hz.

When testing in The Netherlands is complete, CHEOPS will return to Airbus Defence and Space Spain in Madrid for the final preparations before being shipped to Europe’s spaceport in Kourou, French Guiana, for launch.

About CHEOPS

CHEOPS is an ESA mission implemented in partnership with Switzerland, through the Swiss Space Office (SSO). The University of Bern leads a consortium of 11 ESA Member States contributing to the mission and represented in the CHEOPS Science Team. ESA is the mission architect responsible for overall mission definition and procurement of the spacecraft and launch. ESA is also responsible for the early operations phase that will be executed by the spacecraft contractor, Airbus Defence and Space–Spain (ASE). The science instrument is led by the University of Bern, with important contributions from Austria, Belgium, Germany and Italy. Other contributions to the science instrument, in the form of hardware or science operations, are provided by Hungary, France, Portugal, Sweden, and the United Kingdom. CHEOPS will be launched from Europe's spaceport in Kourou, French Guiana, on a Soyuz rocket operated by Arianespace. Following successful in-orbit commissioning of the spacecraft, responsibility for operations will be taken over by the CHEOPS Mission Consortium, with the Mission Operations Centre under the responsibility of INTA, Spain, and the Science Operations Centre led by the University of Geneva, Switzerland.