Fuelling of the Planck spacecraft

20 April 2009

Fuelling operations for the Planck spacecraft have been successfully completed last week. The filling of the propellant tanks with hydrazine liquid was performed in the S5A building at the Centre Spatial Guyanais (CSG) launch site on 15 and 16 April.On Saturday 11 April the Planck spacecraft was transferred from the S1B building, dedicated to spacecraft preparations, to the S5A building, dedicated to fuelling operations. Upon arrival at the airlock of the S5A building, the spacecraft was removed from the payload transport container (Conteneur Charge Utile, or CCU) that was used to maintain a cleanroom environment during the 5 km transfer from the S1B building. Still secured on its CCU pallet through the launcher adapter ring, Planck was rolled into the S5A cleanroom and readied for the hydrazine fuelling.

|

|

|

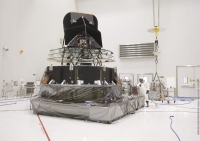

The Planck spacecraft and fuelling equipment during preparations for the hydrazine fuelling in the S5A cleanroom, 15 April 2009. | |

The supply tanks containing liquid hydrazine (N2H4) were brought to the S5A building on 14 April. After being cleaned in the S5A airlock the tanks were brought into the cleanroom of the S5A building for the fuelling operations. Each tank has a capacity of 100 kg of liquid hydrazine, and four tanks were required to provide the 384 kg of propellant for the Planck spacecraft.

|

|

|

Two operators in protective "scape suits" performing preparations for the hydrazine fuelling in the S5A cleanroom, 15 April 2009. | |

The fuelling activity started on Wednesday, 15 April, and was performed by two specially trained operators in protective "scape suits", guided by colleagues who directed and monitored the operations from a nearby safety control room. The spacecraft's three fuel tanks were connected by filling pipes to the tank filling and pressurisation ground support equipment, a dedicated system used to perform and monitor the fuelling of the spacecraft. With the hydrazine supply tanks hanging on a load cell for continuous weight measurement the propellant was pumped under high pressure into the spacecraft's fuel tanks. A total of 384 kg (3×128 kg) of hydrazine propellant fuel was loaded into the fuel tanks in a process which took place during four shifts on 15 and 16 April.

Once the tanks had been filled the fuelling equipment was disconnected and removed from the cleanroom. Upon confirmation that there were no hydrazine traces in the air, the propellant being a highly toxic and volatile fluid, the S5A cleanroom was opened again for normal use.

The final stage of the fuelling operations involves the decontamination of all of the equipment that has been used for the fuelling operations. This means ensuring that the equipment is hydrazine-free at the level of 0.1 part-per-million before the equipment is packed, ready for shipment back to Europe.