Spacecraft

Introduction

| NOTE: In March 2011 ESA announced a new way forward for the L-class candidate missions: IXO, EJSM-Laplace and LISA. At this time the IXO concept ceased to be a candidate and ESA, along with the scientific community, is now investigating to what extent a European-led mission could preserve the original science case of IXO. The new study is called ATHENA (Advanced Telescope for High ENergy Astrophysics).

The ATHENA assessment study report (Yellow Book) is now available. |

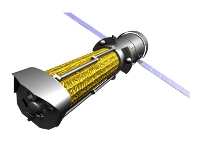

The International X-ray Observatory (IXO) is a collaborative venture between NASA, ESA and JAXA, which is under study for launch in 2020. Initial design studies have been performed in ESA's Concurrent Design Facility (CDF) at ESTEC and NASA's Mission Design Laboratory (MDL) at the GSFC. This article mainly describes the concept that has been derived by the CDL studies, but also presents the major differences between the two concepts.

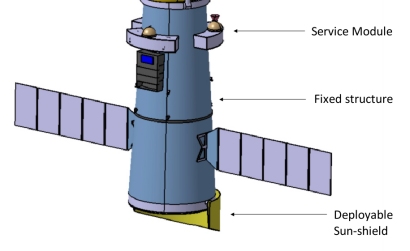

IXO will have a launch mass of around 6600 kg and will be about 10 metres long and 4 metres in diameter in its launch configuration. The spacecraft will be about 23 metres long in its flight configuration. The nominal mission lifetime is five years, with consumables sized for 10 years of operations. A major science driver for the design of IXO is a long focal length, since this allows a greater photon-collecting capability at higher photon energies. A focal length of 20 metres has been selected for IXO as a balance between science requirements and engineering constraints. As no current launch vehicle is capable of accommodating a payload that is nearly 24 metres long, IXO will have a deployable structure to position the instrument module at the mirror focus after launch.

|

|

|

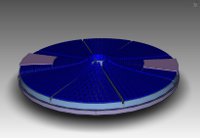

Illustrations of the IXO spacecraft. Credit: ESA | |

The IXO study includes the accommodation of six instruments:

- Wide-Field Imager – WFI

- Hard X-ray Imager – HXI

- X-ray Microcalorimeter Spectrometer – XMS

- High Time-Resolution Spectrometer – HTRS

- X-ray Polarimeter – XPOL

- X-ray Grating Spectrometer – XGS

From the output of the CDF study, the IXO spacecraft will be made up of five major assemblies:

- optics module – mirror assembly with straylight baffle assembly and deployable sunshield

- fixed telescope structure – a 6.7-metre long, 3.4-metre diameter connection between the optics module and the service module

- service module – contains the satellite systems: power distribution, attitude control, propulsion, telecommand and telemetry

- deployable telescope structure – moves the instrument module from the stowed position to the mirror focal point

- instrument module – carries the six instruments, their associated electronics and thermal control systems, and a mechanism for positioning one of WFI+HXI, XMS, HTRS, or XPOL at the focal point (the XGS CCD camera is positioned to the side of the focal plane and operates continuously)

Mirror assembly

| NOTE: In March 2011 ESA announced a new way forward for the L-class candidate missions: IXO, EJSM-Laplace and LISA. At this time the IXO concept ceased to be a candidate and ESA, along with the scientific community, is now investigating to what extent a European-led mission could preserve the original science case of IXO. The new study is called ATHENA (Advanced Telescope for High ENergy Astrophysics).

The ATHENA assessment study report (Yellow Book) is now available. |

The IXO telescope optics is located in the mirror assembly, rigidly connected to the fixed metering structure and the service module. The mirror assembly is designed as a separate spacecraft module, given the specific constraints applicable to its manufacturing, assembly and alignment.

In the launch configuration the mirror assembly is located close to the launch adaptor and protected via dedicated contamination covers. The mirror assembly includes a primary support structure to carry the launch loads associated with the optics elements, the actual X-ray mirror modules with their secondary structure, the thermal control hardware and the contamination protection elements.

The mirror assembly design is based on a highly modular approach, starting at the level of the individual mirror modules and including 8 petals which populate the complete mirror area. Such a modular approach is required in order to be able to cope with the specific assembly, alignment and calibration requirements of X-ray optics.

As mentioned above, the optics module will have an inner and an outer cover to preserve the cleanliness of the mirror during ground handling, launch and spacecraft out-gassing. The outer cover will be ejected in orbit. The inner cover could either be a retractable membrane or a panel that folds as it is retracted out of the path of the X-ray beam.

To prevent illumination of the front of the mirror assembly by the Sun, particularly when the spacecraft performs pitch manoeuvres to access off-axis targets, the optics module will be equipped with a deployable sunshade.

Fixed telescope structure

| NOTE: In March 2011 ESA announced a new way forward for the L-class candidate missions: IXO, EJSM-Laplace and LISA. At this time the IXO concept ceased to be a candidate and ESA, along with the scientific community, is now investigating to what extent a European-led mission could preserve the original science case of IXO. The new study is called ATHENA (Advanced Telescope for High ENergy Astrophysics).

The ATHENA assessment study report (Yellow Book) is now available. |

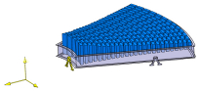

The fixed telescope structure is a 6.7-metre long, 3.4-metre diameter tube, which functions as a spacer to position the mirror assembly sufficiently far away from the service module so that the conical X-ray beam focussed by the mirror can pass through the centre of the service module. The term fixed denotes that the structure has no deployable component. The spacecraft’s solar arrays may be attached to the tube.

The fixed telescope structure could be manufactured from composite fibre-reinforced plastic, with a wall thickness of 1–1.5 mm and 20–40 mm tall ribs for stiffening. The materials and lay-up technique will be chosen to achieve a thermal expansion coefficient close to zero. This will maintain the focal length of the telescope in the various thermal environments encountered during ground testing and on orbit.

One of the primary design drivers for this spacecraft component is the required stiffness of the structure. The launchers impose a strict requirement on the frequency of the first bending mode.

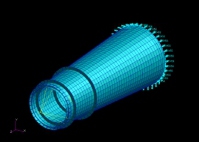

| |

|

Above: Figure depicting different elements accomodated on the fixed metering structure. Left: A finite element model of the fixed metering structure of IXO. Credit: ESA |

The final constraint is that the service module must be large enough to allow the X-ray beam to pass through it. The X-ray beam exits the mirror assembly with a diameter of 3.8 metres for the silicon pore optics and tapers to around 100 mm diameter at the focal plane, some 20 metres away. The service module requires about 800 mm of space inside its walls to accommodate the avionics and propellant tanks. The maximum diameter of the service module is constrained by the launcher fairing to around four metres. Taking into account the clearance required inside each external panel, the hole for the X-ray beam can be 2.4 metres in diameter. This leads to the chosen 6.7-metre length for the fixed telescope structure.

Service module

| NOTE: In March 2011 ESA announced a new way forward for the L-class candidate missions: IXO, EJSM-Laplace and LISA. At this time the IXO concept ceased to be a candidate and ESA, along with the scientific community, is now investigating to what extent a European-led mission could preserve the original science case of IXO. The new study is called ATHENA (Advanced Telescope for High ENergy Astrophysics).

The ATHENA assessment study report (Yellow Book) is now available. |

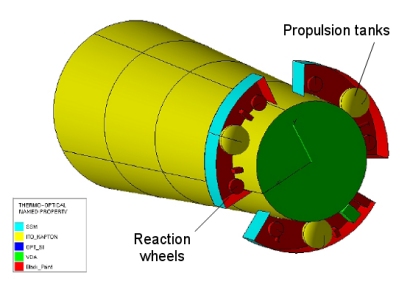

IXO's service module will contain the spacecraft systems such as telemetry and telecommand, attitude control, propulsion, and power distribution. The module will be a polygonal box constructed from a frame with a number of flat equipment panels bolted to it and a bottom panel. During integration and test, the equipment panels will fold down to allow access to the avionics modules mounted on their inner surfaces. The bottom panel will have a 2.4-metre diameter cutout in the centre, to allow the X-ray beam from the optics module to pass through to the instrument module.

The avionics boxes will be positioned on the anti-Sun side of the spacecraft in order to allow heat to be radiated to space. The Sun-facing panels will be fitted with thermal blankets.

The propellant tanks will be symmetrically positioned inside the service module, to minimise the movement of the spacecraft’s centre of gravity as the consumables are expended. Around 330 kg of propellant will be required for attitude control and station keeping at L2 over 10 years.

| |

|

A geometrical mathematical model of the IXO service module with the fixed structure. Credit: ESA | |

|

|

|

Left: A propulsion tank. Right: Instrument control units. Credit: ESA | |

Also housed inside the service module will be five reaction wheels for fine attitude control, inertial reference units, the electrical power distribution system, command and data handling avionics boxes, a small battery, data recorders, and the Ka-band transmitter electronics.

On the exterior of the service module, several triads of thrusters will be mounted. These will be used for coarse attitude control and reaction wheel offloading. The high-gain Ka-band antenna used for communicating with Earth will also be mounted on the service module, as will the Attitude and Orbit Control System (AOCS) sensors (coarse and fine Sun sensors, star tracker).

Mechanical locks will secure the instrument module to the service module during launch.

Deployable telescope structure

| NOTE: In March 2011 ESA announced a new way forward for the L-class candidate missions: IXO, EJSM-Laplace and LISA. At this time the IXO concept ceased to be a candidate and ESA, along with the scientific community, is now investigating to what extent a European-led mission could preserve the original science case of IXO. The new study is called ATHENA (Advanced Telescope for High ENergy Astrophysics).

The ATHENA assessment study report (Yellow Book) is now available. |

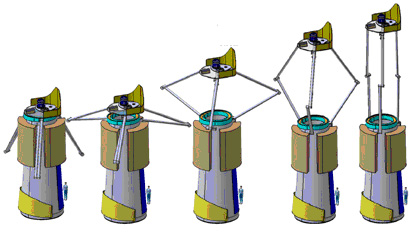

|

|

Three-mast deployment system. |

A major science driver for the design of IXO is a long focal length, since this allows a greater photon-collecting capability at higher photon energies. A focal length of 20 metres has been selected for IXO as a balance between science requirements and engineering constraints. As no current launch vehicle is capable of accommodating a payload that is nearly 24 metres long, IXO will have a deployable structure to position the instruments at the mirror focus after launch.

Two deployment mechanisms are under consideration: extending masts (NASA and JAXA) and stowable, articulated arms (ESA).

Extending masts

Three masts, similar to those used to deploy the ISS solar array wings over a distance of 35 metres, will be stowed in canisters located in the service module.

As the masts deploy from their canisters, they form a repeating series of cubic bays framed by vertical members (longerons), horizontal members (battens), and diagonal cross braces. The longerons and battens are made of graphite rods and the cross braces are stainless steel cables. Motors equipped with position encoders ensure that the three masts extend synchronously to deploy the instrument module.

Articulated arms

Three tubular arms, each with two sections and three joints, are stowed on the outside of the service module, extending over the fixed telescope structure. After launch, the arms are released and a motorised joint in the centre of each arm pushes the instrument module away from the service module.

|

|

Articulated arm deployment system. Credit: ESA |

|

|

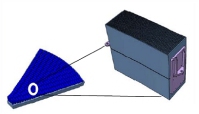

Scale model of the deployable shroud. Credit: NASA-GSFC. |

Shroud

A shroud is required between the instrument module and the service module, to prevent straylight from entering the instruments. The shroud will either surround the deployment masts or be positioned inside the deployed, articulated arms.

The shroud will consist of multi-layer insulation blankets, pleated like camera bellows. The pleats allow the shroud to be stored in a canister on the service module prior to deployment. To minimise light leaks caused by micrometeoroid penetrations, the shroud will be made up of two concentric MLI blankets separated by 100 mm, forming a 'Whipple shield'.

A small-scale prototype of the shroud, constructed at NASA's Goddard Space Flight Center, has demonstrated that IXO's 12-meter shroud can be stowed in a stack just 200 mm tall.

Several baffles will be required inside the shroud, to further block stray X-ray photons. The baffles will be attached to the inside of the shroud and deploy with it.

Instrument module

| NOTE: In March 2011 ESA announced a new way forward for the L-class candidate missions: IXO, EJSM-Laplace and LISA. At this time the IXO concept ceased to be a candidate and ESA, along with the scientific community, is now investigating to what extent a European-led mission could preserve the original science case of IXO. The new study is called ATHENA (Advanced Telescope for High ENergy Astrophysics).

The ATHENA assessment study report (Yellow Book) is now available. |

The instrument module houses a suite of six instruments:

- Wide-Field Imager – WFI

- Hard X-ray Imager – HXI

- X-ray Microcalorimeter – XMS

- High Time-Resolution Spectrometer – HTRS

- X-ray Polarimeter – XPOL

- X-ray Grating Spectrometer – XGS

|

|

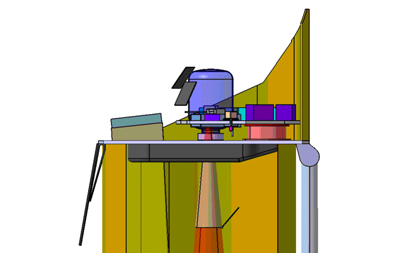

Sectional view of IXO instrument module. Credit: ESA |

Since the X-ray beam from the optics module cannot be folded in the manner typically used in visible-light telescopes, five of the instruments (WFI+HXI, XMS, HTRS, or XPOL) must be rotated into the focus, with only one operating at any given time.

The XGS views X-rays that have been diffracted out of the main beam by gratings, onto a CCD camera at the side of the main focal plane – it operates continuously. The HXI sits behind the WFI and views high-energy X-ray photons that have passed through the WFI's focal plane.

The four instruments / instrument combinations that must operate at the focal point of the main beam will be mounted on a revolving platform with four stops, moved by redundant motors. The movable instruments will have their own fine-focussing mechanisms to allow them to compensate for changes in focus between ground testing and the flight environment.

The XGS CCD camera will have a lateral fine-positioning mechanism so that it can be centred on the X-ray diffraction beam coming from the gratings. The gratings will be located at the end of the fixed telescope structure nearest the service module, or in the service module itself.

All the instruments will be protected from incoming protons in the energy bands of interest by magnets, positioned close to the detectors.

On the platform mounting the movable instruments, the five instruments will need to have electronics boxes housing their signal processing systems – these need to be close to the detectors. Once the sensor signals have been digitised, the data can be sent to additional electronics housed on the underside of the fixed part of the instrument platform. From there the data is sent to the service module for storage and transmission to Earth.

The electronics on the movable instrument platform will be cooled by means of heat-pipe connections to a radiator. The instruments may have their own radiators looking to deep space. The electronics on the underside of the instrument module will also be cooled with heat pipes and a radiator.

A fixed sunshield attached to the instrument module will keep the instruments in shadow at all times. The limitation of spacecraft roll (± 10 degrees) and pitch (± 20 degrees) with respect to the Sun line somewhat simplifies the task of stabilising the thermal environment for the instruments.