#08: New detectors and microshutters for NIRSpec

25 February 2015

The past two months have seen a team of engineers engaged in the intricate activity of replacing key components of the Near InfraRed Spectrograph (NIRSpec) on the James Webb Space Telescope. The instrument is now ready for the next series of extensive environmental tests devised to ensure that JWST's instruments can withstand the stresses and strains of launch and operation in space.In the summer of 2014, the James Webb Space Telescope (JWST) Integrated Science Instrument Module (ISIM), fitted with all four instruments (NIRSpec, MIRI, NIRCam, and FGS/NIRISS), successfully completed cryogenic testing in a '24/7' campaign that lasted 116 days.

However, the positive outcome of this important test campaign did not mean that ISIM and the instruments were ready for integration onto JWST's telescope. It has been known for over a year that additional work would be necessary to get some of the instruments into their final flight configuration. As a consequence, a period of a few months was allocated for these activities, immediately after the completion of the cryogenic test campaign.

In particular, NIRSpec needed to have its detectors, microshutter assembly and optical assembly cover replaced. Also, the NIRCAM and FGS/NIRISS teams had to exchange some components in their instruments. MIRI was the only instrument that remained integrated with the ISIM. However, MIRI's configuration was also updated by installing the flight model cooler Cold Head Assembly (CHA) and exchanging some of the cooler lines and their supports.

NIRSpec detectors

The first generation of JWST's near-infrared detectors suffered from a design flaw that resulted in a progressive and unacceptable degradation of their performance. (Readers who would like to learn more about this issue can find a detailed technical report here.) Once the origin of the problem had been identified and, more importantly, a solution found and verified, new detectors were manufactured for all three JWST near-infrared instruments (NIRSpec, NIRCam, and FGS/NIRISS).

At the end of 2013, the NIRSpec team selected two flight-quality detectors out of the pool of new detectors. These detectors were then integrated in a new focal-plane assembly (FPA). Fortunately, the performance of this new FPA is equivalent to or even better than that with the 'old design' detectors at the beginning of their life (i.e., before they started to degrade).

NIRSpec microshutters

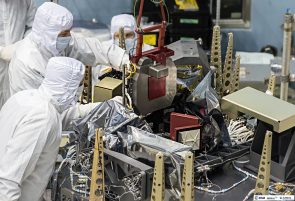

|

| NASA engineers inspect the new microshutter assembly. Credit: NASA/Chris Gunn |

One of the defining, and pioneering, features of NIRSpec is its ability to record the spectra of many (more than 100) objects at the same time. This multi-object spectrography capability is made possible by the use of a Microshutter Assembly (MSA) consisting of just under a quarter of a million individually controlled microshutters, arranged into four quadrants each containing an array of 365×175 microshutters. These microshutters are a new technology that was developed for JWST and is provided by NASA.

At the end of 2012, it was discovered that, after acoustic testing of the instrument (replicating the conditions during launch), several thousand of the individual microshutters had become inoperable and could not be opened. This susceptibility to acoustic noise was not expected and had gone undetected because of the difficulty of reproducing the environment to which the microshutters are actually subjected in this instrument. As a result of this problem, the performance of the microshutters in NIRSpec was strongly degraded.

An Anomaly Review Board was established at NASA and many additional acoustic tests on the microshutters were performed in NASA's acoustic test facility in order to find the cause of the degradation. Tests were conducted both at array level, using a special test fixture, and at instrument level, using the NIRSpec Engineering Test Unit (ETU). The latter provided the most realistic test environment for the MSA. These various tests provided a wealth of information that helped NASA to identify the cause of the 'failed closed' shutters issue.

The design of the arrays was slightly altered and production of new arrays was started. Despite great efforts, NASA did not succeed in building all four necessary 'new design' arrays; this was related to yield issues in the manufacturing process. However, by successfully re-screening 'original design' microshutters that had already been produced, NASA engineers were able to identify a small pool of robust, flight-quality arrays. At the end of the process, the new MSA contains three 'original design' arrays and one 'new design' array. In addition to most arrays being pre-screened at array level, the complete new MSA flight model was acoustically tested in the NIRSpec ETU before it was installed in the flight version of NIRSpec.

In parallel, the lifetime of the mechanism used to move a magnet over the arrays to open the microshutters was greatly improved by the use of a 'super molybdenum disulphide (MoS2)' coating on some of its components. In addition, the material used for the rollers was changed to a harder alloy that, together with the newly applied coating, will minimise wear and potential electrical short-circuits in the MSA.

The overall performance of this new flight-spare MSA is much better than that of the flight MSA previously installed in NIRSpec. As a consequence, it was decided to use the opportunity of the detector exchange to also replace the current MSA with the new spare component.

NIRSpec optical assembly MLI cover

As part of this programme of hardware upgrades it had also been decided to replace the protective cover (multi-layer insulation, or MLI) for the NIRSpec optical assembly because it was showing some signs of wear. While this was not a serious problem, it was thought better to take the opportunity to replace the cover with one of exactly the same design as the original, to be sure that all elements of the instrument were in the best possible condition.

The exchange process

|

| Replacement of NIRSpec focal plane assembly. Credit: NASA/Chris Gunn |

As the process of exchanging NIRSpec's MSA and FPA required the instrument cover to be opened, extreme care needed to be taken not to contaminate NIRSpec's interior. This concern was driven by the known extreme susceptibility of the MSA to particulate contamination, especially small polyester fibres that are found in many items, such as cleanroom garments, lacing cord and clean room wipes. The problem is that, during acoustic testing, these small fibres can enter the microshutters and prevent them from fully closing. These trapped fibres then lead to (partially) failed open shutters in the MSA that seriously affect the science results as spurious light can enter the NIRSpec spectrometer optics at these locations and project false spectra onto the detector.

In order to prevent such contamination, ESA and Airbus Defence and Space, supported by their NASA colleagues, implemented a very strict cleanliness regime during the exchange activities. As the NASA Spacecraft Systems Development and Integration Facility (SSDIF) cleanroom is 'only' certified to ISO Class 7 (Class 10 000) and the NIRSpec instrument was built in Germany under ISO class 5 conditions (Class 100), extra measures needed to be taken. The team managed to get the very cleanest location inside the NASA SSDIF cleanroom, this being the north-western corner, directly in front of the High-Efficiency Particulate Arrestance (HEPA) filter wall. The area was cordoned off and access was greatly restricted.

|

| Lifting the NIRSpec microshutter assembly. Credit: NASA/Chris Gunn |

During the activities, all team members had to wear special cleanroom garments that had previously been demonstrated in Germany to provide better cleanliness levels than that which can be achieved with standard cleanroom garb. This clothing included special garments under the normal cleanroom suits, special double mouth-masks and extra-long white cleanroom gloves. Implementing this new dressing procedure at NASA required a lot of coordination. The support offered by NASA in realising this was much appreciated.

In any cleanroom environment, humans remain the main source of contamination, even if extreme measures are taken to minimise this. For this reason, the NIRSpec exchange area needed to be 'screened and cleaned' on a daily basis. Every other day, the team had a dedicated early morning time slot where the SSDIF lights were switched off and, by using special 'Crime-lite' light sources, the complete area, scaffolding and instrument were screened for the presence of particulates, particularly fibres. During these time slots, the area and hardware were vacuum cleaned and wiped with special tissues. The recorded data, taken continuously throughout the two-month exchange period, confirmed that the team did an excellent job. Very high levels of cleanliness were maintained, occasionally rivalling what was achieved in Germany.

|

| Exchange complete. Credit: NASA/Chris Gunn |

After demonstrating that the exchange area was very clean, the first task was to remove the NIRSpec instrument cover to gain access to the detectors and MSA. All the optical surfaces were then protected to prevent damage or contamination. The old detector system was removed and its replacement was installed, aligned and connected, after which a functional test was performed.

The second stage of the exchange process involved removing the existing MSA and installing, connecting and aligning the new one. Again, a functional test was performed, followed by an inspection to ensure cleanliness before installing the cover.

The exchange process was executed successfully during December 2014 and January 2015 by a team that included engineers from Airbus Defence and Space (the prime contractor for NIRSpec), ESA and NASA. NIRSpec is now ready to be installed on ISIM again.

Later this year, the instruments on ISIM will begin an extensive programme of environmental tests to reproduce the conditions they will have to withstand during the launch and once they are in space. These tests will include vibration and acoustic testing as well as a third cryogenic test campaign. Throughout the course of the testing, the health of the MSA will be regularly checked by high magnification optical inspections with a specialised camera set-up.

About JWST

The James Webb Space Telescope (JWST) will be a general-purpose observatory with a 6.5-metre telescope optimised for infrared observations and a suite of four astronomical instruments capable of addressing many of the outstanding issues in astronomy. The primary aim is to examine the first light in the Universe – those objects which formed shortly after the Big Bang. Further aims include: looking at how galaxies form; the birth of stars; and the search for protoplanetary systems and the origin of life, including the study of exoplanets. JWST is a joint project of NASA, ESA and the Canadian Space Agency. It is scheduled for launch in 2018 on an Ariane 5 and will operate approximately 1.5 million kilometres from the Earth in an orbit around the second Lagrange point of the Sun-Earth system, L2.

About NIRSpec

The Near InfraRed Spectrograph (NIRSpec) is one of four instruments on JWST. NIRSpec is a multi-object spectrograph capable of observing more than 100 astronomical objects simultaneously. It will support JWST's four main science themes by providing low, medium and high-resolution spectroscopic observations.

NIRSpec was built by European industry to ESA's specifications and managed by the ESA JWST Project at ESTEC, the Netherlands. The prime contractor is Airbus Defence and Space GmbH (formerly EADS Astrium GmbH) in Ottobrunn, Germany. The NIRSpec detector and microshutter array (MSA) subsystems are provided by NASA's Goddard Space Flight Center.