X-ray Mirrors

Introduction

|

|

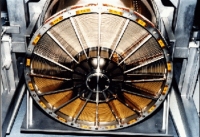

58 nested Wolter I |

Configuration

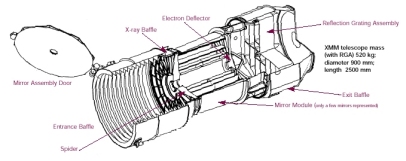

Each of the three XMM-Newton telescopes consists of:

- the mirror assembly door, which protected the optics during integration, launch and early orbit phase

- the entrance baffle, which provides visible straylight suppression at angles larger than 47°

- the X-ray baffle

- the mirror module

- an electron deflector, which produces a circumferential magnetic field which prevents low energy electrons reflected by the mirrors reaching the focal plane detectors

- the Reflection Grating Array (only in two of the three telescopes)

- the exit baffle, which provides an appropriate thermal environment

|

|

Scheme of one of the XMM-Newton telescopes |

The 58 Wolter I mirrors of each telescope are bonded on their entrance aperture to the 16 spokes of a single spider made out of Inconel (a nickel alloy). The spider is connected to the support platform via an aluminium interface structure (the MIS: Mirror Interface Structure) consisting of an outer cylinder and an interface ring. On two of the modules, the ring interfaces the mirror module to a Reflection Grating Assembly (RGA). To minimise the mechanical deformation of the mirrors and therefore the optical degradation, the flatness of the interface between the spider and the MIS had to be better than 5 micron.

X-ray baffles are located in front of the mirror systems. They act as collimators and reduce considerably the amount of straylight in the field of view of the focal plane cameras.

|

|

|

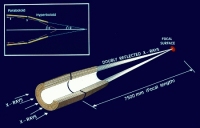

Light path in the XMM-Newton telescope with only an EPIC camera in its primary focus (left), and in the two telescopes in which a RGA is mounted into the optical path (right). |

|

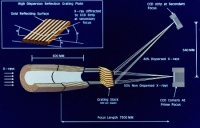

The XMM-Newton X-ray baffle was constructed as two sieve-plates made out of circular strips. The plates were mounted coaxial to and coaligned with the front aperture cross section of the 58 mirror shells, such that they block single-reflection rays, but do not eclipse two-reflection rays. Each sieve plate is a disk 1 mm thick with 59 circular strips and 16 radial spokes. The offset of the two sieve plates from the front of the mirror system is 385 mm and 439 mm, respectively. All the baffle surfaces facing the mirrors are blackened.

Optical Design

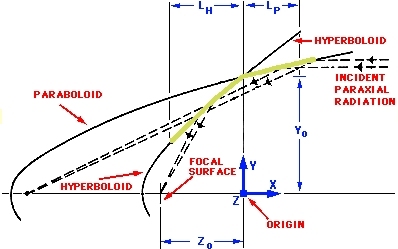

Each mirror module is a grazing-incidence Wolter I telescope, consisting of 58 gold-coated nested mirrors. Each mirror shell consists of a paraboloid and an associated hyperboloid which were replicated together in one piece to facilitate alignment and integration.

|

|

Optical design |

In grazing incidence optics the effective area is increased by nesting a number of mirrors and thus filling the front aperture as much as possible. The nesting efficiency is determined by the mirror shell thickness and, in case of very low grazing angles, by the minimum radial mirror separation which is required for integration and alignment. The thinner the mirror shells are and the narrower the shells are spaced, the larger is the collecting area.

The thickness of the smallest mirror (diameter = 306 mm) is 0.47 mm, and it increases linearly with shell diameter in order to guarantee sufficient stiffness. The thickness of the 700 mm diameter mirror is 1.07 mm. The minimum radial separation between adjacent shells is 1 mm. Adding more shells is rather inefficient in building up more collecting area because of the mass penalty involved and the low gain in effective area.

Telescope Specifications | |

| Telescope focal length | 7500 mm |

| Number of mirrors per telescope | 58 |

| Outer mirror radius | 350 mm |

| Inner mirror radius | 153 mm |

| Axial mirror length | 600 mm |

| Outer mirror thickness | 1.07 mm |

| Inner mirror thickness | 0.47 mm |

| Minimum packing distance | 1 mm |

| Mirror substrate material | Nickel |

| Reflective Coating | Gold |