22 May - 8 June 2000

9 June 2000

The first part of the reporting period saw mechanical and thermal work on FM 6, FM 7 and FM 5, inside the PPF while the RCS (Reaction Control System) system of FM8 was verified inside the HPF. On 2 June the last SVT test, for FM 5, was completed. In the last days of the reporting period the filling with NTO (N2O4 = nitrogen tetroxide, the oxidiser for the combustion of the spacecraft propellant) of the first Cluster pair, FM 6 and FM 7, took place.8 June

|

|

Before and after moving, both empty and full containers were checked for leaks with a vapour detector |

Today, after finishing filling of the FM 6 and FM 7 spacecraft with the NTO oxidiser, it was time to remove the empty NTO containers from the HPF and replace them with MMH fuel containers. At the same time additional helium bottles were transferred to the HPF.

Even though this operation is not performed inside the HPF, it is considered as a hazardous activity. This is the case for all activities, which involve moving the NTO or MMH containers. A fire truck was standing by ready to intervene if necessary.

A Starsem team performed the transfer of the MMH containers, under Astrium Propulsion and ESA supervision, up to the airlock door, then the Astrium team took over the work and moved the fuel inside the HPF.

7-8 June

Alignment activities are completed on FM 8.

FM 7 has been filled with 405 kg of NTO oxidiser. The NTO drums are then removed and the MMH propellant drums are installed in the HPF for the second stage of the fuelling with 245 kg of MMH.

A flasher test has been performed on the FM 8 spacecraft. Battery conditioning of FM 6 and FM 7 is still nominally on-going.

6 June

Some relief! The FM 7 transponder came back to Baikonur, with the charter flight carrying part of the ESA and the industrial team, after having revisited the Western part of Europe for a period of 1 week! It had suffered a small anomaly (low-power output) which required some verification and a minor repair in Spain, where it was developed.

Its trip from and back to Baikonur via Moscow and Amsterdam was the trickiest part of this hurried action, which was necessary in order not to jeopardise the schedule. Indeed, the communication between Moscow and Baikonur and the customs clearance in Moscow for such type of hardware are very complex, long and delicate, requiring lot of sweat, pressure and patience.

The transponder will be reintegrated after the filling operation in the UCIF clean room.

In the meantime, the spacecraft fuelling operations have started on time with FM 6 being filled with 405 kg of NTO (the oxidiser for the combustion of the spacecraft propellant) inside the HPF clean room. This delicate operation is monitored by the specialist engineers from a control room located well outside the hazardous area near our offices! Only the technicians in charge of the filling and the fire brigade on stand-by are allowed to be in or next to the HPF clean room. The quantity of propellant (flow and total quantity) is carefully controlled by weighing the spacecraft.

5 June

After pressurisation was completed on FM 6 and FM 7, filling operations were able to start the following day.

This is one of the key milestones in the launch campaign. Indeed, when the spacecraft start to be fuelled, it is very difficult to stop the operation or even worse to step back for any activity! The spacecraft are then considered as hazardous items and any unforeseen activity would require verification and approval from the quality insurance and from the safety authorities.

Meanwhile, in the PPF clean room, mechanical and thermal activities are continuing on FM 5 and FM 8 with boom deployment, integration of boosters for boom and RCS valves.

The conditioning of the batteries for the FM 6 and FM 7 spacecraft has started and will proceed until 17 June, with 2 shifts, 7 days a week, 24 hours a day. The work is performed by engineers from ESA, Astrium (Dornier) and FIAR.

3/4 June

FM 7 was also transferred to the HPF for the preparation of the second step of the pressurisation operation before the filling operations.

2 June

|

|

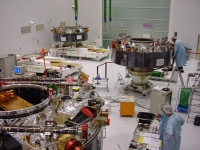

Unfortunately not all 4 S/C together because the objective was not wide enough even when we tried to climb on top of the clean room ladder |

The last electrical tests on FM 5 have been completed with the execution of the SVT (System Validation Test) with ESOC (European Space Operations Centre in Darmstadt). This was the last SVT test for all spacecraft. ESOC is therefore ready to command the spacecraft and to receive telemetry from them via the Network Data Interface Unit (NDIU).

A unique moment: all 4 spacecraft are together for a short time in the same clean room. This will be the one and only time that this will happen in Baikonur! Then, FM 6 was transferred to the HPF room for the preparation of the second step in the pressurisation operation before the filling operations.

1 June

The battery test equipment has been checked and calibrated before the real start of the activities.

Now, all the pyros for the boom deployment and the RCS (reaction control system) valves have been completed for the FM 6 and 7 spacecraft, just on time in view of the battery conditioning and tank filling which will take place next week.

Before the delicate filling operation due to start on June 6, there has been a successful review to ensure that:

- The HPF clean room was fully operational and safe for the filling operation (including checking of the protective 'scape' suits and training with them)

- All filling and decontamination procedures were approved both by ESA and by Starsem

- The spacecraft and the ground support equipment were ready for this operation

31 May

Batteries are also prepared for integration onto the spacecraft i.e they are slowly awakened from their hibernation! They were nicely sitting in their freezer at -15 °C and their temperature will be raised from -15 °C up to 20 °C, step by step over several days.

The batteries are used for power supply during the 4 hour-long eclipse when the spacecraft enters the Earth shadow. Due to the nature of the mission, the batteries are non-magnetic, like all the components of the spacecraft. Therefore, they are not of the classical Ni-Cd (nickel-cadmium) type but made of Ag-Cd (silver and cadmium). They are located inside the spacecraft on the equipment platform in order to ensure a good thermal environment.

The final alignment verification has started for all spacecraft, beginning with FM 6, the front runner spacecraft. These verifications concern mainly the position of all the thrusters and some experiments. It is the last activity for all spacecraft before the battery conditioning and the spacecraft fuel filling.

29-30 May

|

|

Flasher tests with from left to right: Wolfram Beckert, Frederick Spaeth and Elizabeth Haeberle from Dornier |

Flasher tests have begun on the first spacecraft (FM 6) in the PPF (Payload Processing Facility) clean room. These tests check the behaviour of the solar panels, which provide electrical power to the spacecraft. The curved solar panels (6 per spacecraft) are attached to the outside of each satellite. During the tests, each solar panel is illuminated and its output power is checked. These tests are performed overnight in order not to disturb the other members of the team.

The FM 6 and FM 7 spacecraft have been transferred to the HPF (Hazardous Processing Facility) clean room for the start of pressurisation ready for fuelling the week after. Pressurising the spacecraft's helium tanks is the first step in the process of filling and fuelling the spacecraft. In flight, the inert helium gas will be required to force the oxidiser NTO (N2O4 = nitrogen tetroxide) and fuel MMH (monomethylhydrazine) into the combustion chamber of the main engine and the eight thrusters on each satellite.

27 May

The missing boosters, which arrived the night before, were immediately installed on the FM 7 (on 27/5) and FM 6 (on 29/5) spacecrafts, after careful unpacking from the explosafe container. Despite the low quantity of powder (around 0.1 gram: the charge equivalent to that of a very small firecracker), they were installed with great care under strict PA supervision, performed by Manfred Schmidt and Arrien Tiemon. The boosters (four gas and two liquid) together with the initiators (one nominal + one redundant) were installed on all the pyrovalves of the RCS system (six per spacecraft in total).

|

|

The gas booster (in bag) with the 2 initiators with the design principle |

The principle of the boosters is a two-stage process: first, one of the initiators is activated then the booster explodes and normally the redundant initiator as well if everything goes all right. This explosion triggers the opening or closure of the valve depending on the design. Obviously, the initiators are for the time being unarmed to avoid any problem. The arming is one of the last operations on the spacecraft and will take place a few days before launch through an access door (hatch) in the fairing of the launcher.

The activities with the installation and the verification of the solar array have started: the flasher test set-up is installed and ready to be operated over night in order to minimise disturbance for the other teams working on the spacecrafts.

26 May night

|

|

Explosafe container |

May 26 - 21:30 (local time) was a great moment for the launch team. The explosafe container containing 14 small boosters for the spacecraft was loaded inside our van on the tarmac of Yubileiny airport in Baikonur for transport to the Energia hall, where our spacecraft are prepared for launch. The story started one week ago when these boosters were sent from California to Baikonur to be delivered in the shortest time possible, in order not to jeopardise the schedule of the launch campaign.

The shipment was engineered by Herman Thoma from the Estec Transport and Customs office at Noordwijk, with the support of ESA Moscow office and Starsem for the leg in Russia.

First, the boosters were transported by cargo plane from San Francisco to London via Amsterdam. To save time, the box was intercepted at Amsterdam airport and placed inside a special container (explosafe container) to comply with IATA dangerous goods regulations for air transport for the leg in Europe. The customs clearances and the trip from Amsterdam to Moscow were arranged in one day. Once it arrived at Moscow, our troubles started due to the lengthy customs clearance process and the lack of airline communication between Moscow and Baikonur. There are basically only two commercial flights per week from Moscow with little possibility of cargo shipping. There are daily military flights but are usually not available for private companies. After several attempts, it was clear that in the middle of the week, there was no chance to get these boosters in Baikonur before the end of the week. This was in fact the limit for the launch team in order not to affect our schedule.

In view of the situation, late in the evening of 25 May, the ESA Cluster 2 project took the decision to arrange a special charter to transport the boosters for the next day. After a long time getting the last custom authorisations to load the container, the charter plane left Moscow at 16:03, local time, which was 3 minutes over the limit for the closure of Baikonur airport. Fortunately, this remained open and manned thanks to the good relations between Starsem and the local authorities. The plane arrived 3 hours and quarter later at the Yubileiny airport of the cosmodrome where it was welcomed by a small team consisting of Gallina Matthieu and Gerard Gradel from Starsem, Wolfram Beckert from Dornier, our Russian translator and myself (Daniel de Chambure) from ESA. It was quite emotional to see our so long expected boosters arriving in the middle of steppe after such a long journey!

There, the customs clearance with the Kazakhs were conducted in less than 10 minutes, after I confirmed to them that I was the owner of the precious shipment. After a slow drive for half an hour on the bumpy roads of the Cosmodrome, the container was brought to the air lock clean room, where it was opened the next day. After another one hour drive we were back at the hotel around 23:00 where the event was celebrated with a glass of beer!

Unfortunately, there is no picture from this event as the airport is a military one. I tried to ask but I almost got my camera confiscated!

26 May

Every Thursday, work permitting a visit is organised for some of us at the Baikonur Cosmodrome Museum which is close by. The museum is quite interesting and shows the space history of the Soviet Union and now Russia, since its beginning with Sputnik. It covers the creation of Baikonur, the first flight of Joeri Gagarin, all the Proton and Soyuz successes, MIR and Energia-Buran. The recent period with the cooperation with ESA is also not forgotten (MIR mission; microgravity experiment; ISS etc.).

25-26 May

|

22 - 23 - 24 May

This week has seen intense activity, though not very exciting, lots of small mechanical and thermal work to be completed before the end of the week when the first so-called 'hazardous' activities will take place i.e. mounting of the gas booster charges for the pyro-units of the RCS (Reaction Control System) and fuelling of the spacecraft.

In detail, the situation is as follows:

- The FM 6 is inside the PPF clean room together with FM 7 and FM 8. All three are undergoing mechanical and thermal activities, mainly on the RCS. These activities include final torquing of all subsystems, fixing of stand-off for mounting the thermal blankets, thermistor integration, Teflon protection installation on some thrusters and detailed visual inspection.

- In the mean time, FM 5 currently in the HPF clean room is completing its RCS functional tests (pressure calibration; leak checks; valve functioning, etc.)

|

|

Torque verification performed by Joerg Mueller (Dornier) under supervision of Arrien Tiemon (ESA) |

Activities have also started to move one of the OCOEs (Operational Check-Out Equipment) and COTEs (Check-Out Terminal Equipment) to the UCIF (Upper Composite Integration Facility) in view of the the mating of the Cluster stack with the Fregat, which should take place at the end of June. This equipment is electrical ground support equipment, for the operation of the satellite. They will be moved once again to the launch pad when the spacecraft will be mated to the launcher and transported to the launch pad.

A nice touch for every member of the Cluster Launch Campaign team who has his birthday during the campaign receives a bottle of vodka. Yesterday, it was Ulrich Woessner (Dornier). Today, it was the turn of Gunter Schuler (Dornier).