First Gaia mirrors completed

11 January 2010

The Gaia project recently passed another major milestone with the completion of three of the 10 payload mirrors. Final acceptance for the M5 and two M4 mirrors was granted by Delivery Review Boards conducted at the premises of Advanced Mechanical and Optical Systems (AMOS) in Liege, Belgium, towards the end of 2009.

|

|

|

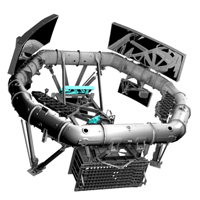

The Gaia M5 mirror (top) and one of the Gaia M4 mirrors (bottom). Credit: ESA |

The three mirrors were fabricated from sintered silicon carbide (SiC) by Boostec at Bazet near Tarbes, France. Silicon carbide has an extremely high Young's modulus (420 GPa, compared to 70 GPa for Zerodur or 60–90 GPa for CFRP) allowing the construction of a light but extremely stiff structure, important not only for the performance of the mirror in service, but also for minimising deformations caused by Earth's gravity field during on-ground characterisation.

To fabricate the mirrors, SiC powder was mixed with a binding agent and moulded at a pressure of around 1,400 bar. The resulting 'green body' blank was then machined to shape, a task made more difficult by the extreme abrasiveness of the SiC powder. The machined blank was heated to in excess of 2,000°C to sinter the SiC, that is, to cause the particles of SiC powder to adhere to one another without actually melting them. After sintering, the mirror blank was ground to shape and lapped to achieve a flat surface.

As it is made of bonded particles, sintered silicon carbide cannot be polished to give an optically smooth surface. The required surface characteristics were achieved by coating the mirror surface with a layer of silicon carbide using chemical vapour deposition (CVD). The CVD layer of all Gaia mirrors is applied by Schunk Kohlenstofftechnik in Heuchelheim, Germany.

The requirements for the M5 mirror specified an RMS wavefront error of

The M4 and M5 mirrors will be delivered to EADS Astrium for integration onto the Structural Model (STM) of the Gaia Payload Module (PLM). Once the PLM STM has been integrated and aligned, it will be used for a range of mechanical tests. Among the most important of these will be the release tests for the bipods that support the optical bench during launch. These bipods carry the launch loads exerted by the optical bench, but then have to be released, leaving the bench supported by much lighter bipods – thus achieving the required mechanical characteristics for the optical bench mounting in orbit. The PLM will also be subjected to vibration tests to simulate the launch environment, with telescope boresight alignment tests conducted both before and after vibration to ensure that the telescope performance will be maintained after launch.

The integration, alignment and testing of the PLM STM will take around 9.5 months. The STM will then be refurbished as the proto-flight model.

|

|

|

Illustration showing the location of the M4 and M5 mirrors. Credit: ESA | |