Gaia mirrors ready to shine

15 September 2011

ESA's Gaia mission has passed another major milestone after the completion of 10 state-of-the-art mirrors that will be used to measure the precise positions of a billion stars. With the delivery of the last of these complex mirrors, Europe has further reinforced its position as the world leader in silicon carbide mirror technology.Gaia will be the most advanced astrometry mission ever flown. The space observatory is designed to scan the entire sky and to pinpoint the locations of about one thousand million stars in our Galaxy. The position of each of its target stars will be measured about 70 times during the five-year mission.

In order to carry out this unprecedented stellar census, Gaia will carry two telescopes that point in different directions in order to study widely separated areas of the sky. Each telescope comprises four identical sets of mirrors (M1 to M4). Two additional mirrors (M5 and 6) are used by both telescopes to direct the light into the same focal plane.

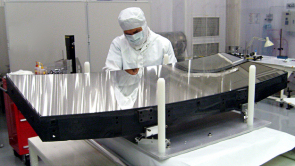

Although the mirrors are all rectangular, they vary considerably in size and shape. The primary mirrors (M1) are concave and measure 1.46 × 0.51 m, while the convex secondary (M2) mirrors measure 0.35 × 0.16 m.

|

|

| One of two primary mirrors, M1 | One of two secondary mirrors, M2 |

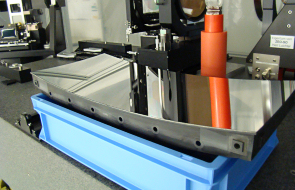

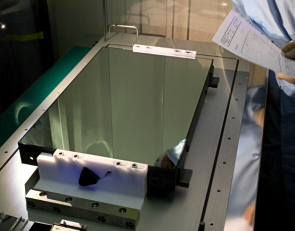

Light from the latter pair is reflected onto the concave, tertiary (M3) mirrors, whose dimensions are 0.65 × 0.28 m. The optics are completed by the flat M4 combiner mirrors (dimensions 0.19 × 0.07 m), and the M5 and M6 mirrors (dimensions 0.55 × 0.34 m).

|

|

|

Left: One of the two tertiary mirrors, M3. Right (above): One of the two combiner mirrors, M4. Right (below): The M5 mirror. |

|

All of the mirrors were fabricated from blanks made of sintered silicon carbide (SiC), which were made by Boostec in France. After preliminary grinding and lapping to achieve a flat surface, all of the mirror blanks were sent to Schunk Kohlenstofftechnik in Heuchelheim, Germany, where they were coated with a layer of silicon carbide, using a process known as chemical vapour deposition (CVD).

Driven by mission deadlines which require the entire optical assembly to be combined and tested well in advance of Gaia's launch, ESA managers decided to use different contractors in France, Belgium and Germany for completion of the mirrors.

The final lapping and polishing was a slow, meticulous process which required each mirror to be shaped to a precision of about 10 nanometres (10 millionths of a millimetre) RMS. The remarkable smoothness of the resulting surfaces means that, for example, if the Gaia M1 mirror was scaled to the size of the Atlantic Ocean, any bumps on the surface would be only a few centimetres high.

Each of the 38 kg primary mirrors was shaped by the French company Sagem, located close to Paris. The M2, M4, M5 and M6 mirrors were milled and polished by AMOS of Liege, Belgium; and the M3 pair was produced by Carl Zeiss Optronics GmbH in Oberkochen, Germany. In addition, two flat mirrors required for testing of the telescopes were made by Sagem.

| Gaia's payload module with its 10 mirrors. The light path for one of the two telescopes is indicated in blue. For larger versions of this video click here |

The final phase in their manufacture involved the addition of layers of reflective coating, using a process known as physical vapour deposition (PVD). During this process, which was carried out in high vacuum at temperatures between 150 and 500

The result has been a set of 10 mirrors with outstanding physical and optical characteristics, and an industrial team with unrivalled expertise in SiC mirror manufacture.

"Since the design process began in 2006, the Gaia team has learned how to produce a set of sintered silicon carbide mirrors which is not only extremely strong and ultra-stable – with about twice the rigidity of steel - but also lightweight and with a high thermal conductivity," said Matthias Erdmann, ESA's Gaia Payload Systems Engineer responsible for optics and ceramics.

"Although these are not the first silicon carbide mirrors that have been made for a space mission, no mirrors as large as the Gaia primary mirror have previously been coated using the CVD process," he added.

"The degree of similarity of the mirror pairs is also quite unique. This is particularly important for Gaia, since each telescope must have similar optical capabilities, with diffraction limited viewing and minimal wavefront errors. Their outstanding optical characteristics achieve new standards that will be of great value to the development of future space observatories.

"As a result of this programme, the European industrial team has been able to master all of the processes required for making state-of-the-art space mirrors, and become the world leader in silicon carbide mirror technology."

In July this year, one complete set of telescope mirrors integrated on the Payload Structural Model was subjected to vibration tests at the Intespace test and integration centre in Toulouse, France. The tests confirmed the stability of the assembly and demonstrated that the optical path will not change when the spacecraft will experience the loads generated during the launch.

The integration of the last two mirrors of the second telescope is now ongoing, so that the entire optical system can be aligned. This will clear the way for the flight Payload Model to be completed and give the green light to a series of functional and performance tests in the thermal vacuum chamber.

Contacts

Matthias Erdmann

Gaia Payload Systems Engineer

Email: matthias.erdmann esa.int

esa.int

Phone: +31 71 56 58885

Giuseppe Sarri

Gaia Project Manager

Email: giuseppe.sarri esa.int

esa.int

Phone: +31 71 56 54966