The Gaia torus is complete

28 July 2009

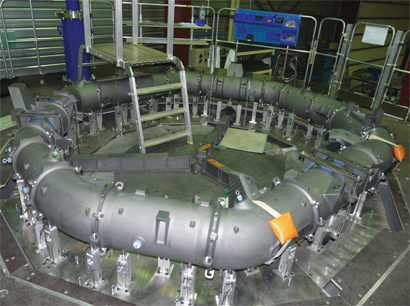

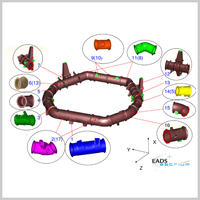

At the end of June the Gaia mission passed a significant milestone when the 17 individual segments of the torus, a key structural element of the spacecraft, were brazed into one coherent structure at the BOOSTEC premises at Bazet near Tarbes, France. The successful results of this process were concluded after a Mandatory Inspection Point of the torus on Monday 20 July 2009.The 3-metre diameter, quasi-octagonal torus, which will support the two Gaia telescopes and the focal plane assembly, is composed of 17 individual custom-built Silicon Carbide segments.

|

|

|

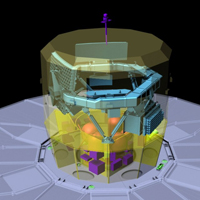

Figure 1 Illustration of the spacecraft showing the location of the torus. Credit: ESA/AOES Medialab |

Figure 2 The torus is composed of 17 individual elements as shown here. Credit: EADS Astrium |

Construction of the individual segments began 15 months ago at BOOSTEC. In the intervening period the individual segments have been milled, sintered and lapped. Each element has been subject to stringent quality checks and has undergone static-proof tests to confirm the mechanical integrity of the pieces. (See "Constructing the Gaia torus" for further details.)

Silicon carbide for light-weight, robust structuresThe scientific requirements of the mission (for example, astrometric measurements accurate to 24 microarcsec (at V= 15 magnitude)) translate to a requirement for a payload platform that is mechanically and thermally ultra stable. For these reasons all elements of the torus are constructed from Silicon Carbide (SiC), a ceramic material whose physical characteristics make it the material of choice for structures which must be both light-weight and robust. The low thermal expansion coefficient and high thermal conductivity of SiC mean that it is a very stable material which can quickly dissipate thermal gradients, and with a Young’s Modulus of about 420 GPa it is twice as stiff as steel.

Final steps: assembly, alignment & brazingStarting on 28 April the torus began to take shape as the individual elements were assembled together and precision aligned using laser trackers and reference points on the torus segments. A special braze paste was applied to the interface points between each of the segments (Figure 3). When heated above 1000 °C this paste melts and seals the joints by capillary action - the torus then becomes one complete unit.

The completed torus was placed in the brazing furnace at BOOSTEC on Wednesday 24 June and remained there until the morning of Monday 29 June. After a cooling-down period the torus was removed from the furnace and moved to the laboratories for post-brazing quality control. This included a thorough visual inspection of external and internal surfaces – the latter by means of borescopes - and ultrasonic inspection to confirm the integrity of the structure.

(The furnace at BOOSTEC was built for brazing the Herschel 3.5-metre diameter primary mirror, and has also been used for the optical bench for the JWST NIRSPEC instrument.)

Torus complete - payload module assembly to followOnce the torus will be delivered to EADS Astrium, the Gaia prime contractor, at Toulouse, the assembly of the Payload Module, including the torus and mirrors, will next begin.