Inertial Sensor Head shaken but not disturbed

12 December 2013

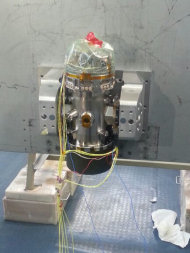

The Engineering Qualification Model of the Inertial Sensor Head (ISH) for LISA Pathfinder has passed a significant milestone. The integration of all the components of the ISH with perfect alignment, and the successful completion of qualification tests mark the first time that a heavy test mass inertial sensor has been assembled and successfully tested.

|

| Schematic diagram of the Inertial Sensor Head. Credit: RUAG & CGS |

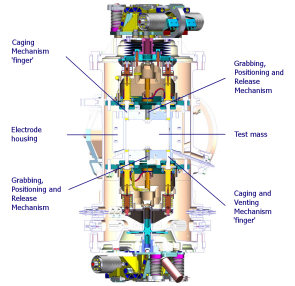

There are two Inertial Sensor Heads (ISH) on either end of the LISA Technology Package, mounted to a Zerodur support structure, to which the optical bench is also fixed. Each ISH carries a test mass, which will be free floating once the spacecraft is on orbit. Each of these test masses will be floating inside a set of parallel electrodes, which measure the distance from the mass to its walls. The distance between the two test masses will be measured using a laser interferometer, to confirm that the masses can be maintained in a genuinely free-floating condition inside the spacecraft and that the distance between them can be measured with sufficient accuracy and noise level. These elements will be vital for any future gravitational wave detection mission, which will need to place the masses much farther apart in space.

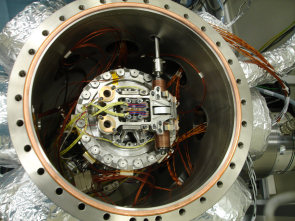

Creating the correct environment for the test masses poses several challenges: the structure must be perfectly aligned down to micron level, even when it is subjected to the extreme acoustic and mechanical environment of launch. The vacuum enclosure, which is almost 43cm tall and almost 18cm in diameter, must avoid magnetic components: for this reason it was constructed from titanium instead of the more conventional steel, and special feedthroughs were required for UV fibres and electrical cables. The ISH must be constructed from low outgassing materials, to attain a high vacuum level, and this vacuum level must be preserved up to launch. The Caging and Venting Mechanism, which functions as a launch lock, ensures that any tiny air pockets – "virtual leaks" from within the environment – are vented to space, preserving the vacuum.

The Caging and Venting Mechanism has eight 'fingers' that retain the test mass during the launch of the spacecraft. Once the spacecraft is in free flight, the 'fingers' relinquish control of the test mass and the Grabbing, Positioning and Release Mechanism (GPRM) takes over. The positioning mechanism must release the test mass with a positional accuracy of approximately 200 μm in all three planes and with a velocity of less than 5 μm/s. The GPRM must also be able to re-grab and re-release the test mass if required.

The ISH structure has several units, which were successfully brought together for this test. The Engineering Qualification Model (EQM) of the ISH comprises:

- a gold:platinum test mass,

- a representative electrode housing,

- two Grabbing, Positioning and Release Mechanisms

- a launch lock, incorporating a venting gate valve, called the Caging and Venting Mechanism

- a titanium vacuum enclosure,

- UV fibre feedthroughs,

- electrical harness feedthroughs.

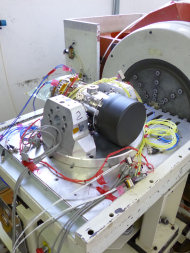

Rigorous testing was carried out at subsystem level before the ISH could be integrated and tested. For example, a special test rig at the University of Trento, Italy, was used to check that the Grabbing, Positioning and Release Mechanism can release the test mass with the required accuracy.

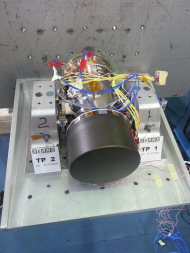

The mechanical performance of the ISH during launch was verified by a series of tests. The campaign included vibration testing in three planes, carried out by CGS at the Centro Technica in Milan, Italy. After a functional test of the mechanism by which the test mass is handed over from the CSV to the GPRM, the ISH was first subjected to swept-sine vibrations at low level, to determine its characteristics and to reveal any mechanical resonances not predicted by the design models. The ISH was then subjected to random vibrations at qualification level – these tests verify the overall design of the ISH. This was followed by a random vibration life test (three cycles at acceptance level – to verify that the performance satisfies the specifications). The life test simulated the mechanical life of the unit, prior to and after launch. After another swept-sine test to detect any changes, the ISH was brought to the premises of SERMS in Terni, Italy, where it was subjected to shock tests. At the end of the testing, another functional test was performed.

The ISH also underwent a thermal vacuum test, checking that alignment was maintained and the vacuum was not compromised at temperatures from -10°C up to 50°C. The normal operational limits will be 0°C to 40°C. The Caging and Venting Mechanism was also put through functional tests at high and low temperatures. One test cycle was also carried out at 125°C, primarily as a mechanical test of the vacuum requirement. There was some additional outgassing of non-flight model components but the "bake out" was successfully completed over five days.

The mechanism was then life-tested by performing the caging and decaging procedure for 60 operational cycles. At the end of the test campaign, the ISH was dismantled, inspected and an alignment check was performed.

The integration of all the components of the ISH with perfect alignment, and the successful completion of the tests mark a major milestone for LISA Pathfinder. It is the first time that a heavy test mass inertial sensor has been assembled and tested successfully anywhere in the world. All flight model elements of the ISH have been delivered and work continues on the LISA Technology Package, due for completion in November 2014, after which it will be delivered and integrated into the spacecraft.

About LISA Pathfinder

LISA Pathfinder is a European Space Agency mission to test the technology required to detect gravitational waves in the range of 0.1 to 100 mHz. The mission will demonstrate critical technologies for future gravitational wave observatories, in a space environment. These technologies include: inertial sensing, drag-free attitude control, and interferometry with free-falling mirrors.

An industrial team led by the prime contractor, Astrium Ltd, is building LISA Pathfinder. Astrium GmbH is the payload architect for the LISA Technology Package (LTP). The Inertial Sensor Heads (ISH) are supplied by CGS.